STRETCH AND SHRINK

Shrink wrap and stretch wrap are made of plastic, typically look similar and serve the same purpose. However, there are two major differences between the two: the wrapping technique and the typical application.

Our story

Wrapping Technique

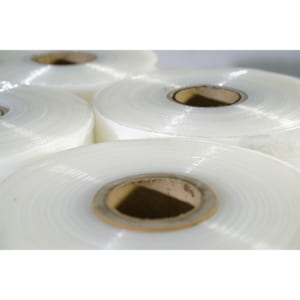

Stretch wrap is applied by stretching the film to wrap it around several boxes and then releasing it which causes the plastic wrap to shrink back to its original size, keeping the products tightly bundled together.

Shrink wrap, as the name suggests, also works by the material being shrunk around the goods.

However, this is done by applying heat to the material and then letting it cool off. Shrink film is first loosely wrapped around the goods and then heated to 100 to 150ºC using a special machine, usually a heat gun, a shrink tunnel or a shrink oven.

Stretch wrap is a staple in any commercial warehouse. It is usually used to wrap boxed goods together in preparation for pallet shipping. It provides a safe way to transport large quantities of items while keeping them neatly packages throughout the journey.

Shrink wrap is more commonly found in shops and it’s used to display various products. In wholesale stores, you’ll usually see large shrink-wrapped pallets of goods and in regular supermarkets, you can see bottles of soft drinks and other products on display wrapped together with a thick transparent stretch film.