Pallet stretch wrap is available in hand and machine rolls. Hand rolls are shorter and lighter. Machine rolls are longer and wider and can weigh in excess of 100 lbs. Most machine stretch film rolls are available in 20″ to 80″ wide. Hand rolls often range from 10″ to 18″ wide.

Other than noticeable physical traits, one of the main differences between hand and machine stretch wrap is the film stretch rate. The stretch rate is the percentage of stretch a film can obtain before tearing. A high stretch rate doubles the roll length, which reduces film waste and cost.

1.Hand Stretch wrap

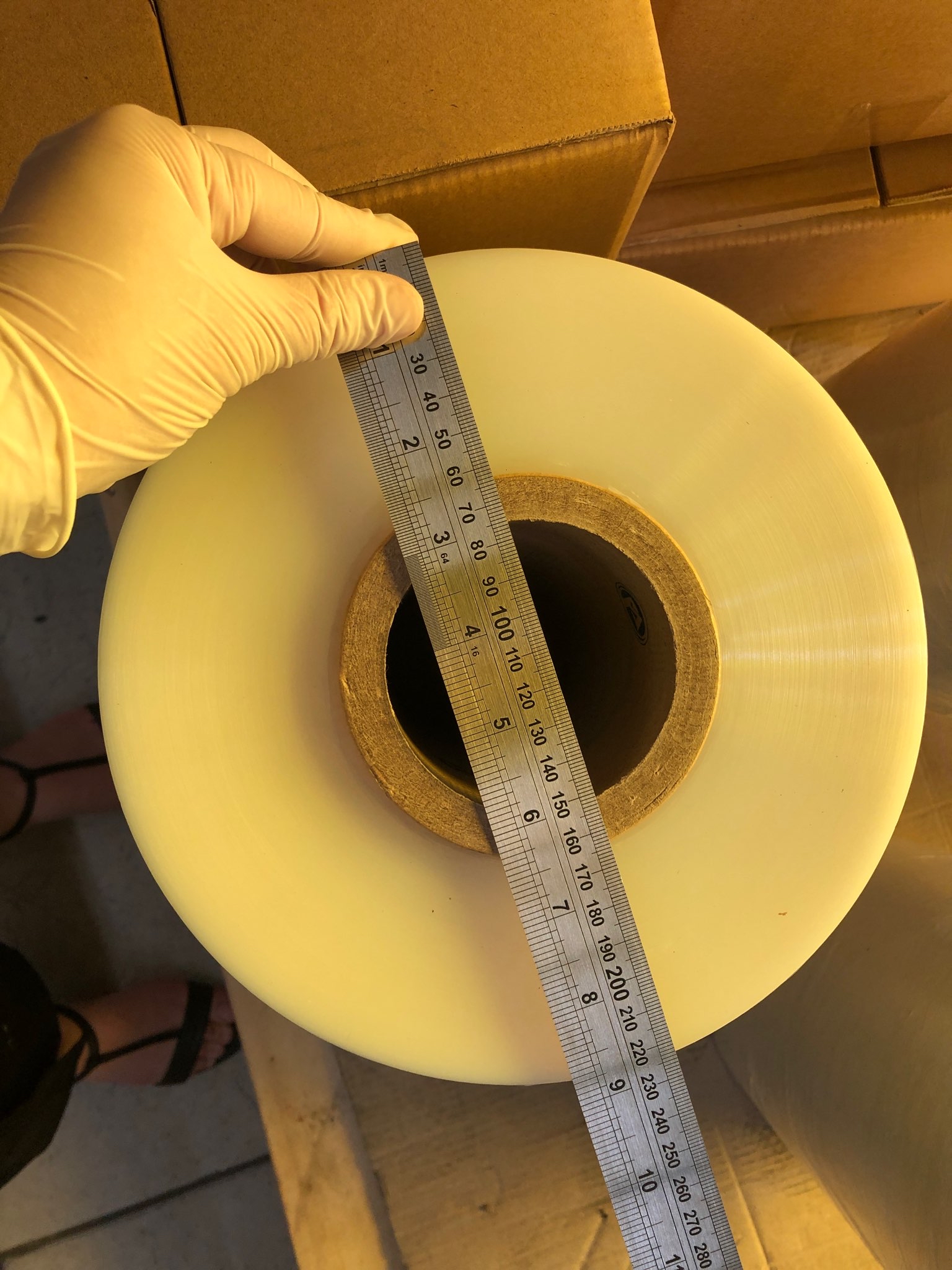

Hand stretch wrap is made for hand applications, therefore rolls are shorter and lighter. Hand rolls often range from 1000 ft to 2000 ft. long. The most popular hand stretch wrap length is 1500 ft. rolls. Rolls range from 5-9 lbs. in weight.

Multiple thicknesses are available depending on the item(s) being wrapped. Pre-stretched hand stretch film can be as thin as a 30 ga thickness. Heavier hand film can be up to a 130 ga thickness. Thicker film offers higher puncture resistance and increased film memory. It also requires harder tension to reach the maximum stretch rate.

A standard 80 ga. hand stretch wrap typically has a 150% to 300% stretch rate depending on the manufacturer.

2.Machine Stretch wrap

Standard machine stretch wrap comes in 20″ wide rolls. Widths can vary up to 80 inches wide, but require special machine film carriages to fit the rolls into the machine. Wider rolls are used for tall pallets to reduce the amount of revolutions required to wrap a full wrap.

Like hand stretch wrap, machine film comes in a wide range of thicknesses. Pre-stretched machine stretch film can be as thin as a 30 ga thickness. Thicker film is available up to a 150 ga. or 1.5 mil thickness. Thicker machine stretch wrap has excellent stretch and puncture resistance for wrapping heavier pallets with sharp and jagged edges.

The ability for a machine to maintain a consistent tension allows much higher film stretch rates. Machine stretch film offers higher stretch rates up to and beyond 300% to 450% stretch rates are standard. The type of film being used and the stretch wrap machine settings are the two biggest factors in obtaining maximum film stretch rates.

3.Conclusion

At HANPAK JSC, we supply customers both hand & machine stretch wrap

For getting the highest quality film rolls, please don’t hesitate to contact us via:

Emaill (Skype): info@hanpak.com.vn

Phone (Whatsapp): +84 906 966 371

Thanks & Hope to cooperate with you!!