As people have an increasing sense of environmental protection, people are more likely to use environment-friendly materials in a different area. It’s non-woven fabric.

Such trend can be proved by the development of the non-woven fabrics market, which is estimated to grow from USD 22.62 Billion in 2016 to USD 31.85 Billion by 2022. Compared with plastic bags, Nonwoven bags are more reusable, which means more friendly to the environment. Compared with the woven bags, they are more affordable and easier for mass manufacture. That’s why increasing people use non-woven bags.

One of the examples is that the popular use of electricity in the automobile area. More daily, we can see that the Non-woven bags are taking place of plastic bags.

1. What is the material of Non-Woven Bags?

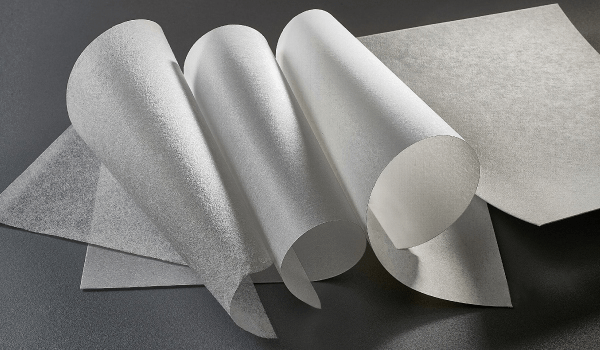

There are four common types of the nonwoven materials

We will introduce these four types of material in the following content.

(1)Spunbound/Spunlace

(2)Airlaid.

(3)Dryland.

(4)Wetland.

(1). Spunbound/Spunlace

Spunbond non-woven fabric is a kind of nonwoven fabric, made of polypropylene. During the process, the polypropylene will be polymerized into a web by high-temperature drawing, and then glued into a kind of cloth by a hot-rolling method. Because of the simple process, large output, non-toxic and harmless to the human body. Therefore, users widely use in various fields such as sanitary materials and so on.

(2). Airlaid

Manufacturers produce airlaid non-woven fabric by the Airlaid technology, which is a new method to produce nonwoven fabric by air webbing and different consolidation methods with wood pulp fiber as the main raw material.

The Airlaid fabric can also be called dust-free paper and dry paper nonwoven fabric. It adopts the airflow web forming technology to open the wood pulp fiberboard into a single fiber state, and then uses the airflow method to make the fiber agglomerate on the web forming curtain, finally the fiber web is reinforced into cloth.

(3). Dryland

Dryland nonwoven fabric is a nonwoven fabric made of staple fibers, a “fiber network” by the dry method and then reinforce by mechanical, chemical, or thermal processing methods.

It is one of the earliest categories of nonwoven fabric. The network consolidation technology includes hot bonding method (including hot melt method, hot rolling method), mechanical network consolidation method (including needle punching method, jet solid network method); “chemical bonding method” (including impregnation method, a spraying method, foam method, printing method, solvent method).

(4). Wetlaid

People make wet nonwoven fabrics from chemical fibers, inorganic fibers, and other fiber materials by “wet forming”. Through the bonding methods like “chemical bonding” or Thermal bonding, producers can form the fiber material into a nonwoven fabric.

It has higher strength, softness, and elasticity than commonly used paper. The main advantage of wet nonwoven production process includes fast production speed, low density of product surface, uniform and fine structure.

Such fabric has been applied in both industrial areas and medical areas, such as the manufacture of medical hygiene materials, interlinings, and functional materials for industrial use……

For more information about Hanpak’s plastic bag products, please contact us:

Email: info@hanpak.com.vn

Hotline (Mobile/WhatsApp): +84 898 545 893

Our experienced sales team is ready to assist you. Contact us today to place your order and experience the quality and reliability that Hanpak offers.