Polyethylene, the most common plastic, was discovered by accident in 1898 and was rediscovered several times after that with chemists and researchers seeing little use for the white, waxy substance.

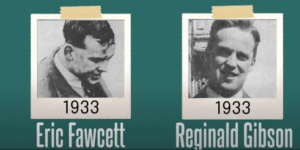

It wasn’t until March 27, 1933, when the first industrially practical polyethylene synthesis was discovered by Eric Fawcett and Reginald Gibson, again by accident, at ICI (Imperial Chemical Industries) in Northwich, England. During high-pressure experiments on ethylene, a test vessel had leaked and a trace of oxygen was present in the chemists’ fresh ethylene sample, acting as an initiator. Polyethylene formed overnight. After some convincing by the chemists, ICI saw plenty of use for the substance and moved toward patents and production.

It wasn’t until March 27, 1933, when the first industrially practical polyethylene synthesis was discovered by Eric Fawcett and Reginald Gibson, again by accident, at ICI (Imperial Chemical Industries) in Northwich, England. During high-pressure experiments on ethylene, a test vessel had leaked and a trace of oxygen was present in the chemists’ fresh ethylene sample, acting as an initiator. Polyethylene formed overnight. After some convincing by the chemists, ICI saw plenty of use for the substance and moved toward patents and production.

Production that involved promotion of the polymerization at mild temperatures and pressures came in 1938, but was soon hushed. Because polyethylene was found to have very low-loss properties at very high frequency radio waves, commercial distribution in Britain was suspended at the outbreak of World War II. Polyethylene itself became veiled in secrecy and the production process was used to produce insulation for UHF and SHF coaxial cables of radar sets.

During WWII, further research was done on the ICI process and in 1944 Bakelite Corporation and Du Pont began large-scale commercial production under license from ICI.

Polyethylene’s production did not become common until the late 1950s and not until the 1970s did the plastic benefit from the incorporation of magnesium chloride for added flexibility.

The potential of plastics and polyethylene received recognition in the 1967 film The Graduate when Mr. McGuire gives Benjamin some career advice: “I want to say one word to you. Just one word … plastics. There’s a great future in plastics. Think about it.”

Indeed, ICI and The Graduate were correct. More than 300 million tons of plastic was produced in 2015 for everything from packaging to construction, electronics, and toys.