Is poly tubing safe for food packaging? Learn about food-grade materials, FDA compliance, safety standards, applications, and how to choose the right plastic tubing for food use.

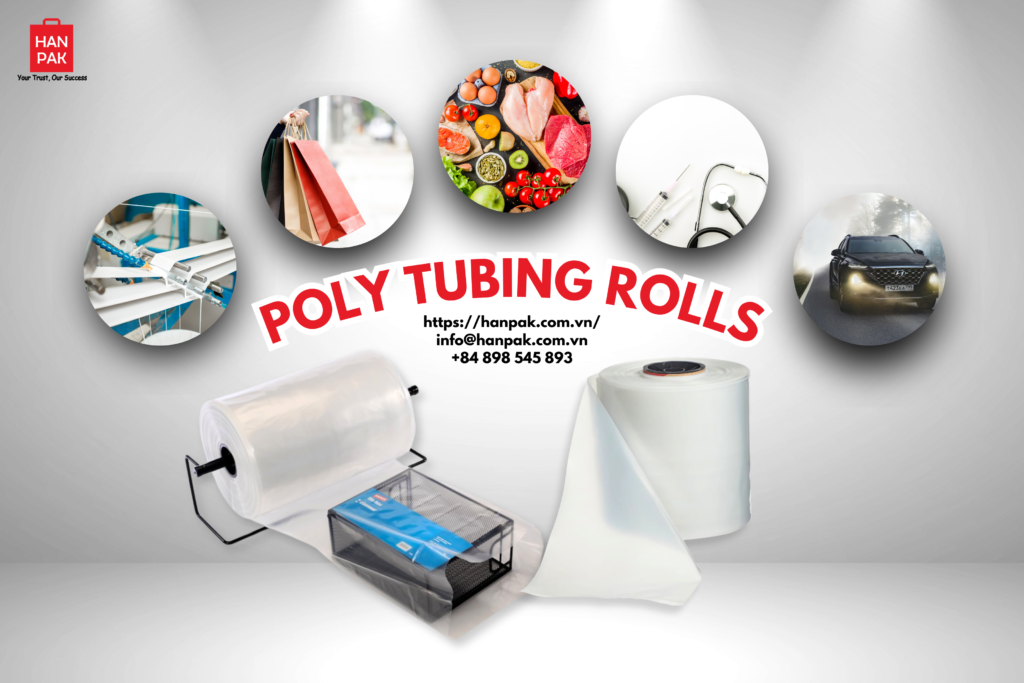

1. What Is Poly Tubing?

Poly tubing is a continuous roll of polyethylene plastic tubing made from LDPE, LLDPE, or HDPE. Users can cut the tubing to any length and heat seal the ends to create custom-sized bags.

Poly tubing is widely used in food packaging because it offers:

- Flexible sizing

- Fast packing efficiency

- Reduced material waste

- Cost-effective packaging

Common applications include fresh food, frozen products, bakery items, agricultural products, and bulk food ingredients.

2. Is Poly Tubing Safe for Food Packaging?

👉 Yes – poly tubing is safe for food packaging when it is manufactured as food-grade material.

Food-grade poly tubing must meet the following requirements:

✅ Virgin Raw Materials

- Made from 100% virgin polyethylene resin.

- Free from recycled content, heavy metals, and harmful additives.

- Odorless, non-toxic, and chemically stable.

✅ FDA & EU Compliance

- Complies with FDA 21 CFR 177.1520 for food contact in the U.S.

- Meets EU food contact regulations (EU 10/2011).

- Certificates of Analysis (COA) and compliance documents are available upon request.

✅ Controlled Manufacturing Process

- Produced in hygienic environments with strict quality control.

- Stable extrusion temperature and clean production lines.

- No prohibited additives used.

3. How Does Poly Tubing Protect Food Products?

Food-grade poly tubing provides excellent protection during storage and transportation:

🛡 Moisture and Dust Protection

Prevents moisture absorption and contamination from external particles.

❄ Suitable for Frozen Applications

Remains flexible at low temperatures and resists cracking.

🌬 Reduces Cross-Contamination

Creates a sealed barrier against bacteria, odors, and external exposure.

📦 Easy Heat Sealing

Strong seals reduce leakage and product loss.

4. Common Applications of Poly Tubing in the Food Industry

| Industry Segment | Typical Applications |

|---|---|

| Seafood | Frozen fish, shrimp, squid |

| Agriculture | Fresh fruits and vegetables |

| Bakery | Bread, cookies, pastries |

| Meat | Fresh and frozen meat |

| Food Ingredients | Grains, powders, spices |

5. How to Choose the Right Poly Tubing for Food Use

🔍 Thickness

- 30–50 microns: light food products

- 60–100 microns: frozen or heavy products

🔍 Clarity & Haze

High-clarity film improves product visibility and shelf appeal.

🔍 Certifications

Request FDA declaration, COA, and compliance documents for export markets.

🔍 Roll Size & Width

Match with packing equipment and handling capacity.

🔍 Printing Options

Custom printing is available for branding and traceability.

6. Is Poly Tubing Sustainable?

Many manufacturers now offer:

- Downgauged films (thinner but stronger).

- Material optimization to reduce plastic usage.

- Recyclable mono-material structures.

⚠ For direct food contact, virgin material is still recommended to ensure safety compliance.

7. Conclusion

Poly tubing is a safe, flexible, and cost-effective solution for food packaging when produced using food-grade virgin materials and certified manufacturing processes. It offers excellent protection, easy customization, and reliable performance for a wide range of food applications.

Businesses should always work with experienced manufacturers who can provide clear compliance documentation and consistent quality control.

How to Contact Us

For more information about our Produce Bags on Roll made by Hanpak, or for any other plastic packaging solutions, please reach out to us:

- Email: info@hanpak.com.vn

- Hotline (Mobile/WhatsApp): +84 898 545 893

Our friendly team is always ready to support you. Contact us today to place your order and experience the quality, reliability, and convenience of Hanpak’s products!