What is PE surface protection film?

PE surface protection film has the English name protection Film, made from pure PE film, then coated with a layer of glue with high adhesion ability. It’s sticky like tape but does not leave glue marks on the surface.

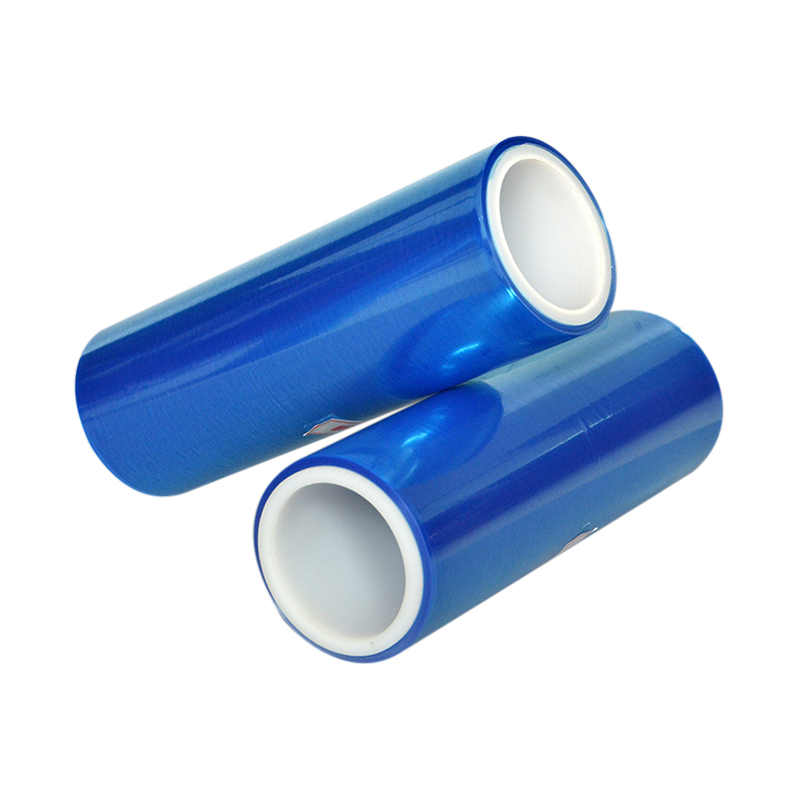

Applications of PE surface protection film

The practical application that stainless steel protective film brings is to surround surfaces. Such as electronics, rough wood, metal, aluminum and glass… from harmful effects from the surrounding environment that can affect the product quality. And it also helps products to be transported easily and stored better.

– Black and white protective film: Used to protect surfaces such as stainless steel, aluminum, steel, advertising signs, etc.

– Blue protective film: Protects floor surfaces for construction projects, plastic, glass, metal surfaces…

– Clear white protective film: Used to protect glass surfaces, LCD screens…

What is the difference between PE protection film and PE stretch film?

People use PE wrap (stretch film) to wrap pallets around goods, or products and packages, to be more secure during transportation. In particular, they often use to package export goods. Or there are types with easy-to-understand applications to preserve food, a very familiar product in today’s families.

Just like the surface protection film, Hanpak also produce film from imported LLDPE virgin plastic beads, has high elasticity, can withstand high impact forces and has good adhesion.

Thus, if we compare these two types of membranes with each other. In essence, scratch-resistant surface film and regular PE film are both made from LLDPE virgin plastic beads. But the difference is that the surface film is usually thicker and has an additional layer of acrylic adhesive, while the chit film has no glue and is thinner, only clear white.

For your further reference, you can explore through our website: hanpak.com.vn.