In many warehouses, PE film works quietly in the background. It doesn’t attract attention, but without it, logistics operations would face serious challenges.

What Makes PE Film So Important?

Poly film is used to:

- Wrap pallets

- Cover machinery and goods

- Protect products from dust, moisture, and scratches

Its role is simple but critical: prevent damage during storage and transportation.

Common Types of PE Film

Each type of PE film serves a distinct purpose:

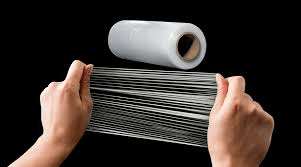

- Stretch film: Secures pallet loads and prevents shifting

- Shrink film: Tightens around products for stable packaging

- PE sheet & roll film: Used for covering, lining, and industrial protection

- Construction PE film: Protects floors, materials, and equipment on job sites

Choosing the right film improves safety and efficiency.

Thickness Matters More Than You Think

Many users underestimate the importance of film thickness. Too thin, and the film breaks easily. Too thick, and costs increase unnecessarily.

An optimized thickness:

- Improves load stability

- Reduces film consumption

- Lowers overall packaging cost per shipment

Professional suppliers often help customers balance strength and material usage.

Why Quality Consistency Is Critical

Inconsistent film quality leads to:

- Frequent film breakage

- Slower wrapping speed

- Higher labor costs

Reliable PE film ensures smooth wrapping, stable loads, and predictable performance — especially important in high-volume operations.

Conclusion

PE film may not be visible to the end consumer, but it plays a crucial role in keeping supply chains moving efficiently. Investing in the right film solution reduces risk and improves operational flow.

For more information about Hanpak’s plastic packaging products and Alibaba shop, please contact us:

Email: info@hanpak.com.vn

Hotline (Mobile/WhatsApp): +84 898 545 893

Our experienced sales team is ready to assist you. Contact us today to place your order and experience the quality and reliability that Hanpak offers.