Wearing disposable gloves in the workplace is important to ensure the safety of both workers and the general public. Gloves help to prevent the spread of harmful bacteria, viruses, and other contaminants that can cause serious illnesses and infections. They also protect workers from hazardous chemicals, biological fluids, and other hazardous materials.

Additionally, wearing gloves helps to maintain a high level of hygiene in the workplace, promoting a healthy and safe working environment. The simple act of wearing gloves can greatly reduce the risk of workplace accidents and illnesses. This makes it a crucial part of any workplace safety protocol.

When it comes to disposable food handling gloves, and particularly loose fit gloves, there are many to choose from. How does one choose the best glove between PE, CPE, TPE, Compostable Gloves? Here is quick guide to understanding the differences, strengths, weaknesses, and benefits of each type of glove:

Polyethylene Gloves (PE)

Polyethylene gloves, also known as PE gloves, are made from low-density polyethylene (derived from oil or petroleum resources). It is the most commonly used type of synthetic gloves. PE gloves are a cost-effective and versatile option for various applications, including handling chemicals, dipping hands into liquids, cleaning, food handling, and medical uses. These gloves are made from a strong and durable plastic that is resistant to oils and solvents. Their non-conductive properties and low elasticity make them easy to remove without breaking the seal. However, they provide limited protection against cuts and should not be used in excessively hot environments.

Chlorinated Polyethylene Gloves (CPE)

CPE gloves are made from a special type of polyethylene that has been treated with chlorine. This makes them more resistant to oils, making them ideal for handling extremely corrosive substances. Like polyethylene gloves, CPE gloves are non-conductive, have low elasticity, and are affordable.

Thermoplastic Elastomer Gloves (TPE)

Thermoplastic Elastomer gloves, also known as TPE gloves, are made from a combination of thermoplastic and elastomers, giving them a rubber-like feel and making them resistant to a wide range of chemicals, acids, and bases.

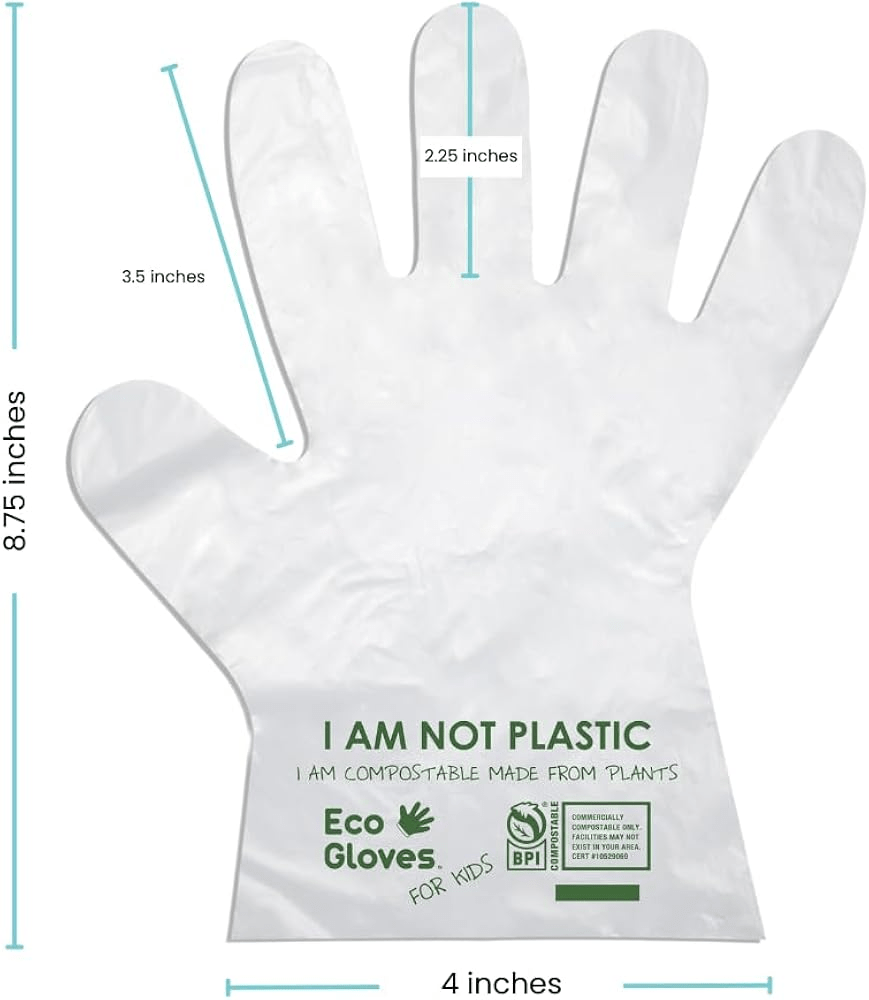

Compostable Gloves

Compostable gloves are made from plant-based materials and are designed to biodegrade in a composting environment. They are made from biodegradable materials, such as starch, corn, or sugarcane. And they are designed to break down and return to the soil when exposed to the elements in a composting environment.

What’s the difference between PE, CPE, TPE, and Compostable Gloves?

The difference between PE, CPE, TPE, and Compostable gloves lies in the material they are made of and the level of protection they provide. To put it simply, PE, CPE, and TPE all are made of plastic and petroleum-derived materials. PE gloves, made from plastic, are the most known type of disposable gloves, particularly for food handling. CPE gloves, made with added chlorine for increased chemical resistance, offer more protection against cuts compared to PE gloves. TPE gloves, made from synthetic rubber, are latex-free, but provide the least protection against cuts among the four. Compostable gloves are also a better environment-friendly alternative to the rest.

Which Glove Should You Choose?

When selecting gloves for your work environment, it’s important to consider some issue. Such as the type of tasks you’ll be performing, the level of protection needed, the gloves’ expected lifespan, and the impact they have on the environment. CPE gloves offer better protection against corrosive chemicals than PE gloves, but they may not be necessary for less severe conditions. PE gloves can provide adequate protection in those instances. However, it’s important to note that all synthetic plastic gloves, including PE and CPE, have a negative impact on the environment and contribute to the growing issue of plastic waste. In such cases, a more sustainable option would be compostable gloves, which are made from biodegradable materials and break down naturally in the environment, minimizing their impact on the planet.

For more information about Hanpak’s plastic bag products, please contact us:

Email: info@hanpak.com.vn

Hotline (Mobile/WhatsApp): +84 898 545 893

Our experienced sales team is ready to assist you. Contact us today to place your order and experience the quality and reliability that Hanpak offers.