Polyethylene including LDPE and HDPE are both thermoplastic materials belonging to the polyolefin family. They are the most common plastic material in the world, are of petrochemical origin, have a simple structure, and are the easiest to produce among commercially available polymers.

Packaging made from polyethylene materials including LDPE (Low Density Polyethylene) and HDPE (High Density Polyethylene) has shaped the market share of the manufacturing and packaging industry. While LDPE excels in the field of lightweight packaging materials such as packaging linings, covers for waterproofing, etc., HDPE excels in sturdy packaging materials such as bottle caps, water bottles, containers and load-bearing structures. In addition, HDPE is also used to produce plastic parts such as water pipes, toys, and plastic chairs.

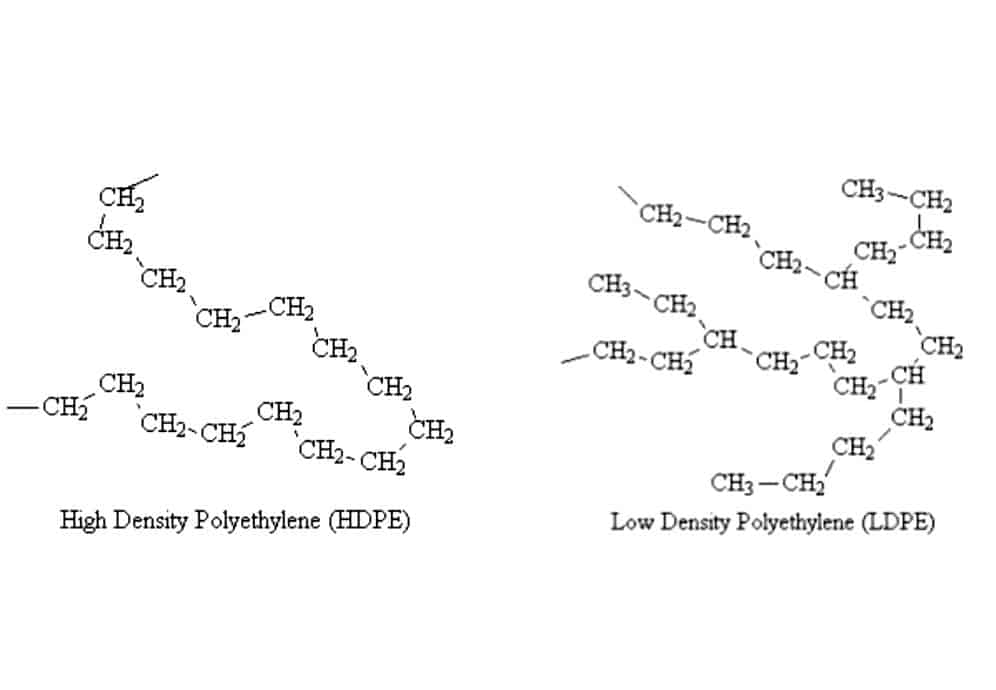

Differences between HDPE and LDPE in physical properties

![]()

Essentially, LDPE is softer and more flexible than HDPE. It has a lower melting point of 110 degrees Celsius and is more transparent. HDPE has a melting point of 140 degrees Celsius with a slightly opaque color and manufacturers often widely use to make bottles, hot food containers, and outdoor water pipes. While LDPE, with its low plastic melting temperature, will be the top choice for heat-sealed bags.

Compensating for these shortcomings, low-density polyethylene plastic provides maximum protection from contaminants, bacteria, ultra-fine dust particles in the air to become the leading packaging in bookstores and food production. They also provide exceptional protection against contamination in the chemical, electronic component manufacturing, pharmaceutical and food industries.

HDPE bags have a rougher, harder appearance. When crumpled, you will hear a rustling sound and leave more wrinkles than LDPE bags.

Load-bearing capacity of HDPE and LDPE plastic bags

The load-bearing capacity of the packaging is the range in which the molecular density of the plastic will have a noticeable effect. High-density polyethylene (HDPE) is the strongest and most durable material. Customers often use as shopping bags in supermarkets. These slim hip bags can hold several dozen kilograms of goods with ease. However, when punctured, they will tear, causing the goods to fall.

Low-density or linear polyethylene resins (LDPE and LLDPE) do not have such strength. But they are flexible because the molecules are located far apart. Tears or punctures will not spread, so this type of packaging is the top choice for carrying sharp objects.

To put it more simply, HDPE bags are hard and have good tensile strength, have little elasticity, are easy to tear but difficult to puncture. LDPE bags are soft and stretch, more easily punctured but difficult to tear.

Differences between HDPE and LDPE plastic bags in chemical properties

The chemical resistance properties of plastic bags are very important in industries, especially when the products they contain are chemically corrosive. Plastic bags are often resistant to chemicals, but there are still chemicals that can react and damage them.

In general, HDPE has better chemical resistance than LDPE. So, they remain the most popular choice for packaging chemical corrosives. However, LDPE bags are still useful against low to mildly corrosive chemicals, so they are still suitable for general use.

Difference between HDPE and LDPE in recyclability

While they are both very recyclable, they cannot be recycled together. The recycling process of the above two materials requires different temperatures due to the difference in melting points.

Another difference is that LDPE bags are more difficult to recycle because their soft structure causes them to get caught in machinery more often than HDPE.

For your reference, you could explore further via our website: Hanpak.com.vn or contact us via our email: info@hanpak.com.vn