When choosing flexible plastic packaging, many businesses struggle between custom poly tubing and pre-cut plastic bags. Both options are widely used across industries such as food packaging, industrial parts, construction materials, and e-commerce fulfillment.

However, the cost structure, operational efficiency, and flexibility of these two solutions are very different. Selecting the wrong option can lead to higher material waste, increased inventory costs, and slower packing processes.

In this article, we provide a clear cost and efficiency comparison between custom poly tubing and pre-cut bags, helping you determine which option best fits your packaging needs.

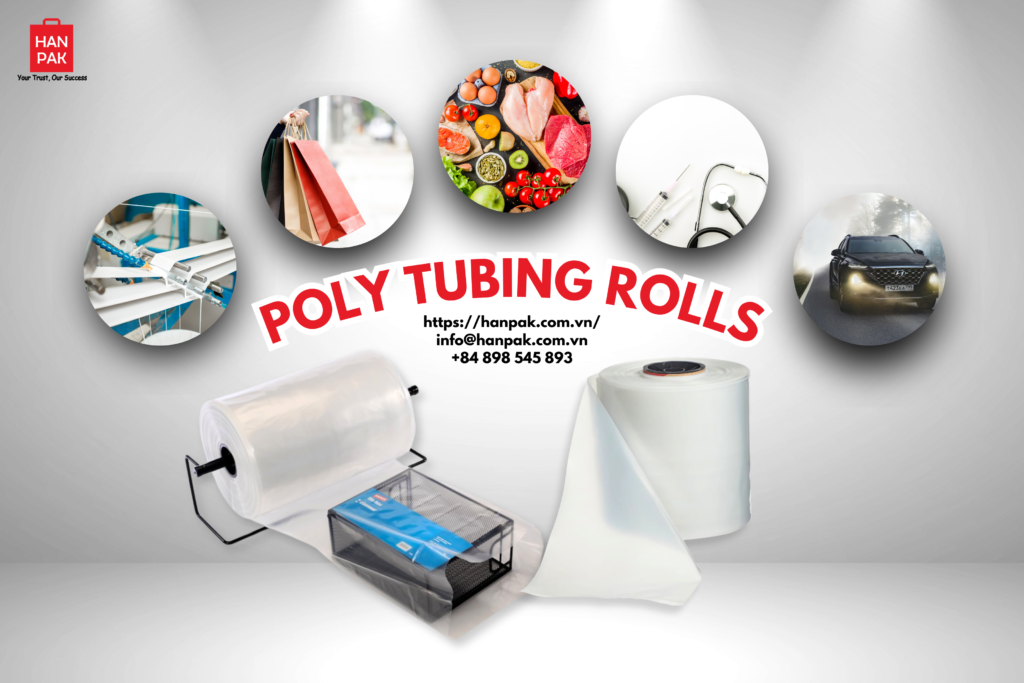

What Is Custom Poly Tubing?

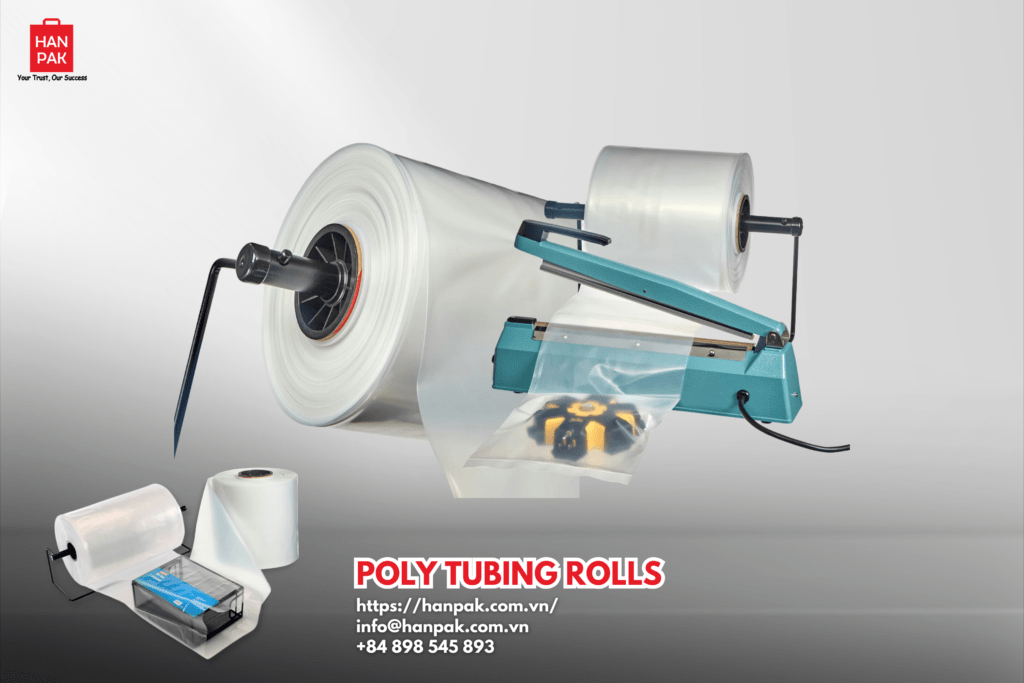

Custom poly tubing is continuous plastic tubing supplied in rolls. It is sealed and cut to length during the packaging process, allowing users to create bags of any size as needed.

Key characteristics:

- Supplied in rolls (continuous tubing)

- Custom width, thickness, and material (LDPE, LLDPE, HDPE)

- Requires sealing equipment (heat sealer or impulse sealer)

- Can accommodate products of varying lengths

What Are Pre-Cut Poly Bags?

Pre-cut bags are plastic bags manufactured at a fixed size and shape. They may be flat, gusseted, or wicketed, and are ready to use without additional cutting.

Key characteristics:

- Fixed dimensions

- Ready-to-pack format

- Available with printing, handles, or zipper closures

- No cutting required during packing

Cost Comparison: Poly Tubing vs Pre-Cut Bags

1. Material Cost Efficiency

Poly Tubing

- Uses only the material required for each product

- Minimal excess plastic

- Lower cost per unit for variable product sizes

Pre-Cut Bags

- Fixed size often leads to unused space

- Over-packaging increases material cost

- May require multiple SKUs for different product sizes

✅ Winner: Poly Tubing

2. Inventory & SKU Management Cost

Poly Tubing

- One roll can serve multiple product lengths

- Fewer SKUs to manage

- Reduced warehouse space requirements

Pre-Cut Bags

- Separate SKUs for each size

- Higher inventory holding costs

- More storage space required

✅ Winner: Poly Tubing

3. Packaging Labor & Speed

Poly Tubing

- Requires measuring, cutting, and sealing

- Slightly slower without automation

- Efficient when paired with semi-automatic sealing machines

Pre-Cut Bags

- Faster manual packing

- No cutting or measuring required

- Ideal for high-speed, standardized operations

✅ Winner: Pre-Cut Bags

4. Equipment & Setup Costs

Poly Tubing

- Requires sealing equipment

- Initial equipment investment needed

- Long-term savings offset equipment cost

Pre-Cut Bags

- Minimal equipment required

- Lower startup cost

- Best for small operations or short runs

✅ Winner: Pre-Cut Bags (short term)

5. Waste Reduction & Sustainability

Poly Tubing

- Reduced plastic waste

- Lower scrap rates

- Supports sustainability goals

Pre-Cut Bags

- Higher risk of wasted material due to oversizing

- Excess plastic increases environmental footprint

✅ Winner: Poly Tubing

Efficiency Comparison Summary Table

| Criteria | Custom Poly Tubing | Pre-Cut Bags |

|---|---|---|

| Material efficiency | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

| Inventory flexibility | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Packing speed | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Setup cost | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Waste reduction | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

When Should You Choose Custom Poly Tubing?

Custom poly tubing is ideal if:

- You package products with varying lengths

- You want to reduce material waste

- You aim to minimize inventory SKUs

- You focus on long-term cost efficiency

- You ship irregular or oversized items

Common industries:

- Industrial parts

- Construction materials

- Furniture components

- Hardware and mechanical products

When Are Pre-Cut Bags the Better Option?

Pre-cut bags are suitable if:

- Your products have standardized dimensions

- You need high-speed manual packing

- You have limited equipment

- Branding or printing is a priority

- You run short-term or seasonal programs

Common industries:

- Retail packaging

- E-commerce fulfillment

- Food service and consumer goods

Cost Example: Real-World Scenario

A manufacturer packaging metal rods in various lengths switched from multiple pre-cut bag sizes to one roll of custom poly tubing.

Results:

- 18% reduction in plastic consumption

- 25% fewer SKUs

- Lower inventory storage cost

- Faster changeover between products

This highlights how poly tubing delivers measurable long-term savings for variable packaging operations.

Final Verdict: Which Is Better?

There is no one-size-fits-all answer.

- Choose custom poly tubing for flexibility, cost control, and waste reduction.

- Choose pre-cut bags for speed, simplicity, and standardized production.

For many manufacturers, poly tubing offers superior cost efficiency over time, especially in B2B and industrial packaging environments.

For more information about our Poly tubing made by Hanpak, or for any other plastic packaging solutions, please reach out to us:

- Email: info@hanpak.com.vn

- Hotline (Mobile/WhatsApp): +84 898 545 893

Our friendly team is always ready to support you. Contact us today to place your order and experience the quality, reliability, and convenience of Hanpak’s products!